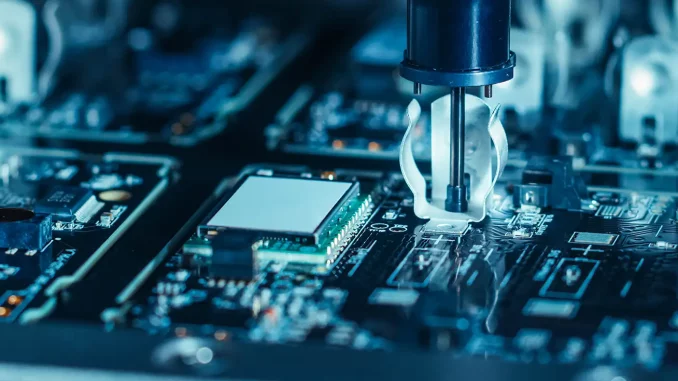

The global chip shortage has been making headlines for quite some time now. The repercussions of this shortage ripple across various industries, especially in the automotive and tech sectors. The dynamics at play are vast, and in this article, we aim to elucidate the multifaceted impacts and their implications for our digital-first society.

- Genesis of the Shortage: At the heart of this situation lies an unprecedented surge in demand for electronics during the COVID-19 pandemic. As households across the globe invested in home office equipment, entertainment gadgets, and tech-enabled education tools, the semiconductor industry grappled with unforeseen demand levels.

- Automotive Industry at a Crossroads: The automotive sector has particularly been hard-hit. Today’s vehicles are more computerized than ever, necessitating a vast number of chips. With the shortage, many automakers have been forced to halt production, leading to dwindling car inventories and surging prices.

- Tech’s Dependency: It isn’t just the car industry. Everyday tech products, from smartphones to laptops, rely heavily on chips. Major tech companies have reported delays in product launches and limited stocks, aggravating consumers and stakeholders alike.

- The Economic Domino Effect: This shortage isn’t just about not getting the latest iPhone or a new car model. The ripples are causing job cuts in related sectors, stock market fluctuations, and shifts in trade dynamics.

- Tech and Auto Ads: With the chip shortage in full swing, technology and automobiles have skyrocketed. Advertisers are competing fiercely for visibility in these high-demand sectors.

- Supply Chain Challenges: One might wonder, why not just produce more chips? The answer is complex. Chip manufacturing requires highly specialized facilities, with some chips taking up to six months to produce. Rapid expansion isn’t feasible.

- Rethinking Strategy: Companies are now re-evaluating their just-in-time manufacturing strategies. These lean strategies, while efficient in optimal conditions, become vulnerable during disruptions, prompting a shift towards more resilient models.

- Shifts in Consumer Behavior: With the delay in availability of new models, consumers are either postponing their purchases or opting for refurbished or second-hand devices and vehicles.

- Innovation in Crisis: Interestingly, the crisis has also fueled innovation. Companies are exploring alternate materials and manufacturing processes to overcome the shortage.

- Governmental Interventions: Recognizing the critical role of semiconductors in the modern economy, governments worldwide are deliberating on measures, from subsidies to tax breaks, to boost local chip production.

- Repercussions for Electric Vehicles (EVs): The EV market, poised for explosive growth, finds itself in a quagmire. These vehicles require even more chips than their traditional counterparts, exacerbating supply issues.

- The Rise of Regional Hubs: To mitigate future crises, there’s a clear push towards regionalizing chip production. This decentralization aims to make the supply chain more robust against global shocks.

- Pandemic’s Silver Lining?: One might argue that this shortage underscores the pandemic’s unexpected silver lining – the rapid digital transformation and tech adoption it spurred across sectors and demographics.

- Future Outlook: While experts predict the chip shortage to ease in the coming years, its impact underscores the need for strategic foresight, diversified supply chains, and continuous innovation.

- In Conclusion: The chip shortage crisis offers a lesson in interconnectedness and adaptability. As industries evolve, it becomes imperative to anticipate challenges, remain agile, and innovate ceaselessly.